Industrial preparation of antibodies requires efforts to produce stable cell lines and commercially viable quantities of pure antibodies. These antibodies are then used for diagnostics, in molecular microbiology or even as a treatment for certain medical conditions.

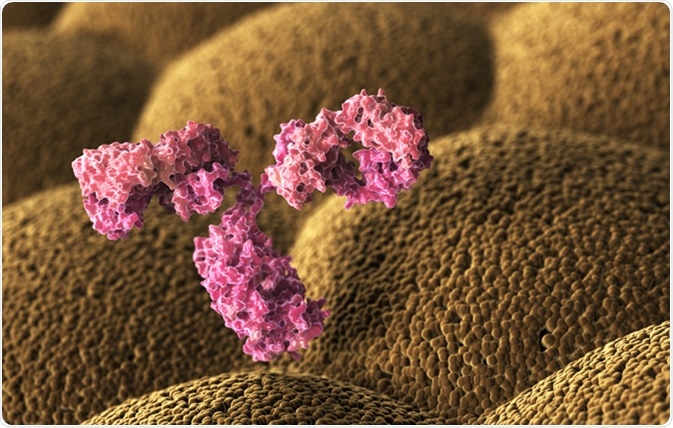

Human antibody (immunoglobulin). 3D illustration. Image Credit: Tatiana Shepeleva / Shutterstock

In vitro Methods

In the in vitro method, antibodies are produced using the hybridoma method, where hybridoma cells are generated by fusing myeloma cells and B-lymphocytes. These lymphocytes may be from a mouse or rat. The target antigen is injected to the animal, and thus the animal is immunized against the antigen. After the animal has generated antibodies, the lymphocytes are extracted and fused with myeloid cells to create hybridomas. This hybridoma cell line is then grown and multiplied in vitro. They secrete antibodies in to the culture medium, from which they are isolated and collected.

After checking for contamination, the hybridoma cell culture is expanded in a roller bottle or agitated cell suspension cultures where they are grown to a cell density of 1-2 X105 cells/mL. They are further cultured for weeks and monitored to check their growth. The hybridoma cells are then centrifuged at 3000-4000rpm for 15 min to separate them from the culture medium. The antibody is collected, and is then sent for further purification. In vitro methods can generate an antibody yield of 15–50mg/L.

Monoclonal Antibody Production

Advantages and Disadvantages of the in vitro Method

The in vitro method provides the flexibility of production scale, which can range from milligram to grams. It has a >95% purity level of antibodies with trace amounts of IgG contamination, and it is cost effective. However, with increasing amount of antibody production, the cost of in vitro production may rise. Based on the cell lines, the in vitro production costs may be 0.5 to 6 times higher than in vivo methods.

In vivo Methods

The initial steps of in vivo production of antibody is similar to the in vitro method, where the antigen is injected in to an animal such as mouse or rat. After the animal generates antibodies, the lymphocytes are extracted to be fused with myeloma cells and hybridomas are generated. In the next step, the expansion of the cloned hybridoma cells is done in the mouse or rat in contrast to a suspension culture used in the in vitro method. Around 1X 106 hybridoma cells are injected in to the peritoneal cavity of each mouse. These hybridoma cells expand in mice as ascites tumors for 7-10days, then the ascites are harvested. The other cells and lipid components are separated by centrifugation to collect antibodies.

Advantages and Disadvantages of the in vivo Method

The use of animals in in vivo method leads to generation of large quantities of antibodies in an easy manner. It can also be used to expand hybridomas which perform poorly in in vitro conditions. However, this method requires adequate animal facilities, and the rate of contamination may be high. Also, this method is painful for the animals, which may raise bioethical issues.

Hollow Fiber Bioreactors

In a hollow fiber bioreactor, hybridoma cells are grown in a compartment where fresh medium can be added continuously to reduce the accumulation of toxic by-products. This method allows the production of high concentration of antibodies.

Purification of Antibodies

Antibodies produced by either method has to be subjected to purification before their use. This step includes centrifugation, filtering, and other isolation methods. In centrifugation, whole cells and cell fragments may be separated from the solution.

Subsequently, it can be passed through an ion exchange chromatography column, where the antibodies can be separated by binding to specific ligands. Antibodies precipitate at low ionic concentrations, and this principle can also be used to isolate them. To separate antibodies, based on their size, electrophoresis may be used.

Further Reading